Composite Recycling has developed a unique process to recover glass fibers from composite material in an economically viable way. Together with the Laboratory of Advanced Composites of EPFL, they are scaling up the process to treat composite waste that is piling up: boats, wind turbine blades etc.

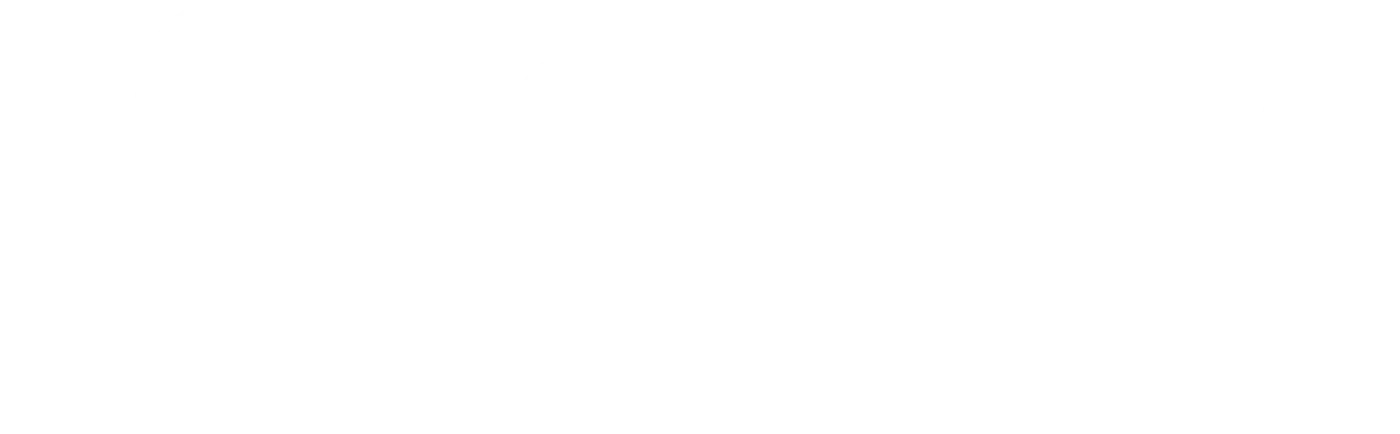

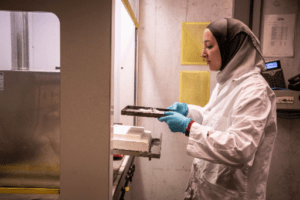

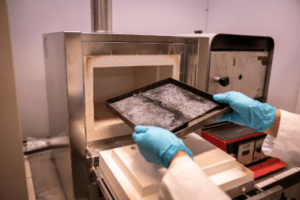

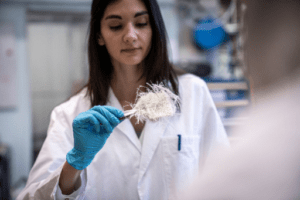

The company’s goal, in alignment with SDG 12: Responsible Consumption and Production, is to make GFRP a circular material. Their technology uses a process called pyrolysis, which heats a material in a low oxygen environment. The output of this process is clean glass fibers and pyrolysis oil. Unlike previous attempts to use pyrolysis to recycle GFRP, Composite Recycling does not require the material to be ground up which allows them to preserve the long glass fibers for resale and reuse in circular products.

Composite Recycling is helping companies that make GFRP products deal with their production wastes so that they can be more sustainable and circular. This could include anything from the waste produced by boat manufacturers to oil drill part manufacturers. During the manufacturing process a lot of scraps are produced, which typically go straight into a non-renewable waste stream, such as landfill. Their technology allows these manufacturers to directly recycle the scrap material at their production site to help them meet their sustainability goals.

Composite Recycling has not yet faced any major challenges in making technology accessible to different communities, however they are still very early in their commercialization and expansion phase.

Composite Recycling aims to make the 2.4 million tons of GFRP waste produced every year circular. The company believes the demand for recycling technologies and circular products is growing at a record rate. Consumers are demanding greener products and governments are regulating end-of-life solutions for waste. Composite Recycling will be one of many wastes stream specific companies which will arise in the coming years to meet this demand.

Useful links: